PRODUCTION PROCESS

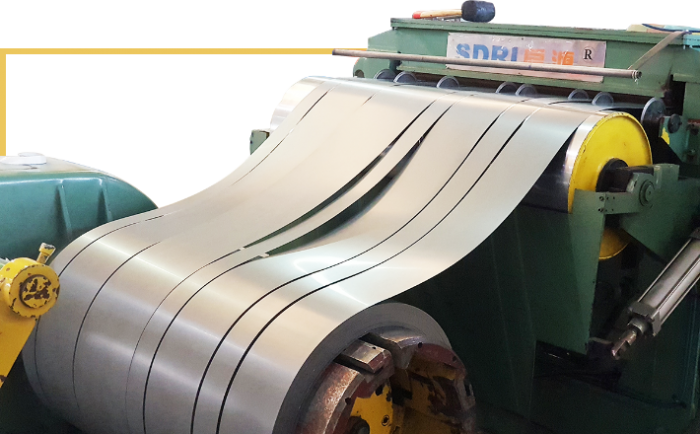

Silicon Steel

A high quality strips of rolled grain oriented magnetic plates with a thickness of 0.27 mm. With low magnetic iron losses and covered on both sides with inorganic insolent, which provides the required interlamination resistance for decreasing eddy current losses. The magnetic steel sheets are slit and cut to length specially designed machines to achieve a high degree of dimensional precision and elimination of burrs.

Magnetic Core

The core strips are carefully assembled and rigidly clamped to ensure adequate mechanical strength to support the windings and prevent shafting the lamination during short circuit

Winding

The winding are designed to optimize dynamic, thermal, mechanical, and electrical stress, depending upon the current and voltage requirements. The LV windings are made by high conductivity electrolytic foil copper and flat copper with high quality insulation paper. This technology enhances the mechanical strength of the windings to withstand short circuit forces. The foil windings have a great advantage because axial short circuit forces. The HV windings are made by high quality of round or rectangular insulated copper conductors.

Assembly of Active Parts

The magnetic core with the windings are assembled together to form the active part of transformers. The windings are slipped over the legs of the core then assembled with the upper yoke plate and supporting steel structure in a horizontal position to avoid mechanical stresses on the active part during this operation.

Final Assembling

At this stage, the upper face of the transformer is installed and performed the following operations

Processing

The factory is equipped with state of the art machinery such as modern tunnel type during ovens as well as an oil treatment plant for drying and degassing of the oil. The drying and degassing process of the oil is controlled automatically. The processed oil is then filled into the transformer tank under environment to ensure full and reliable impregnation of the insulation materials, free of any air voids to guarantee high voltage withstand strength

Insulating Oil

The tank is filled with high quality grade mineral oil per IEC 296.

Corrugating Steel

Cold rolled strip of mild unalloyed steel in coils for corrugated walls in distribution transformers and it’s for thermal exchange with outside area

Transformer Tank

The transformer tank bottom and cover consist of high quality steel plates to ensure durability. The tank walls are built of corrugated steel decreasing overall cost and significantly reducing the size of the product. Through the corrugation, cooling ribs are forms to increase the surface of the tank. This way effective cooling of the insulation liquid is achieved. To ensure the tightness of tank welding, all tank welding is tested with ultra-violate rays. The tank is covered with high quality electrostatic painting.